Cummins Fuel Fuel System - The Cummins Lift Pump

This article is number one in a six part series on the Cummins fuel system (1994 to 1998 equipped with the P pump). This applies to the Cummins 5.9 and 8.3 diesel, as they share the same lift and injection pump. During the prototype stage of designing new products for the P7100 and the Cummins fuel system, we completed hundreds of tests and thought it was necessary to share this information with diesel owners and Cummins performance enthusiasts.

THE BOSCH P7100 IS THE KING OF INJECTION PUMPS

The Cummins 12 valve enjoys incredible popularity because of its simplicity, durability, ease of maintenance and the low purchase price of the truck. Power increases are about as cheap as they get, without the complexity of electronics and fault codes. Power levels in the 400 HP+ range are not uncommon for the Cummns 12 valve, and it can still be driven on the street! The Bosch P7100 (P Pump) is the king in sled pulling competition. Several of these torque monsters exceed 1000 horsepower on only 5.9 liters !!

Let's dig in with some interesting comparisons on the lift pump. The Carter lift pump is a basic hydraulic piston pump. Industrial piston pumps are typically made from high strength castings while the lift pump body is made from an aluminum die casting. Piston pumps rarely use check valves, while our Cummins transfer pump uses three. The piston on a hydraulic piston pump is connected to the swash plate by a connecting rod or with the use of a ball and socket design. The piston in the Cummins lift pump is actuated by a plunger, while the return stroke is by spring pressure. Hydraulic piston pumps have precision ground cylinders and pistons. Our lift pump doesn't share any of the features of industrial pumps, but it is still is a time tested design.

THE PEAK FUEL FLOW NUMBER AND IT'S NOT GOOD

In spite of its draw backs, the lift pump is very reliable! My 98 has 376,000 on the original Cummins lift pump. Unlike its industrial cousin, our lift pump is only 35% efficient at rated RPM. For all of the tests, rated RPM is 2500. 35% is INCREDIBLY LOW, and by the end of article number two, you will know why. With that knowledge in hand, you will be able to increase the efficiency of your system and make HP improvements more easily.

Let's start with a few specs on the Carter lift pump (aka the Cummins lift pump). During the development stage of our fuel products, we collected a large amount of information on the lift pump from shop manuals, diesel forums, and we requested additional information from the manufacturer. Cummins rates the pump at 52.8 GPH (gallons per hour). 52.8 divided by 60 equals .88 GPM (gallons per minute). To be candid, the rated and actual flow ratings were very different.

All of the tests were done using a very precise industrial flow meter with a guaranted accuracy of 1%. It was installed between the lift pump and the Bosch P7100 injection pump. The flow meter is calibrated for water which has a specific gravity of 1. Diesel fuel's specific gravity ranges from .92 to .96, so we have to use a correction factor of 1.0495. All flow meter readings have to be multiplied by 1.0495 to achieve accurate results. (.56 flow meter reading x 1.0495 = .59 GPM) Peak fuel flow of .59 GPM is achieved at 2200 RPM. Fuel flow drops off all the way to the rated speed of 2500.

All of the tests were done using a very precise industrial flow meter with a guaranted accuracy of 1%. It was installed between the lift pump and the Bosch P7100 injection pump. The flow meter is calibrated for water which has a specific gravity of 1. Diesel fuel's specific gravity ranges from .92 to .96, so we have to use a correction factor of 1.0495. All flow meter readings have to be multiplied by 1.0495 to achieve accurate results. (.56 flow meter reading x 1.0495 = .59 GPM) Peak fuel flow of .59 GPM is achieved at 2200 RPM. Fuel flow drops off all the way to the rated speed of 2500.

Normally a piston pump's flow will increase, to a point, as RPM increases (in a well designed system). Not so with the Cummins lift pump. The numbers go down after 2200 RPM. I will explain in detail WHY this takes place, in article number three. Some of you may be thinking that the lift pump is bad because the efficiency is so low. We tested all GPM flows with a brand new lift pump and fuel filter. There were no visible air bubbles in the clear hoses leading to and from the flow meter. 35% efficiency is a very low number and we will explain why.

As mentioned above, we have made several hundred tests using precise flow meters and accurate pressure gauges. Sometimes our assumptions were very close and other times the readings didn't make sense. The findings that didn't match hydraulic principles, forced us to dig deep to find out why. Remember, one good test is equal to a thousand expert opinions.

SOME BASICS ON THE LIFT PUMP

The lift pump has a bore of 1.180 diameter. With the bore diameter and stroke dimension, we can calculate the cubic inch displacement. The stroke dimension appears nowhere in any publication or forum. Without the critcal stroke dimension, it became necessary to measure a cam. The 12 valve Cummins features a cam lobe which activates the plunger on the lift pump (see photo). The cam turns at one half speed of the crank. A good friend, Gabe McKenna of Stallion High Performance, measured his 12 valve cam with a precision depth indicator. My 98 Cummins was exactly the same at .250 stroke. We now have the bore diameter and stroke dimension. Calculating the pump's displacement and GPM flow is very easy.

The lift pump has a bore of 1.180 diameter. With the bore diameter and stroke dimension, we can calculate the cubic inch displacement. The stroke dimension appears nowhere in any publication or forum. Without the critcal stroke dimension, it became necessary to measure a cam. The 12 valve Cummins features a cam lobe which activates the plunger on the lift pump (see photo). The cam turns at one half speed of the crank. A good friend, Gabe McKenna of Stallion High Performance, measured his 12 valve cam with a precision depth indicator. My 98 Cummins was exactly the same at .250 stroke. We now have the bore diameter and stroke dimension. Calculating the pump's displacement and GPM flow is very easy.

Contrary to popular belief, the Cummins lift pump produces flow on the return stroke of the piston, not the forward stroke. Spring pressure on the return stroke, NOT the forward plunger movement, is what produces the flow in the fuel system. In article number three, you will discover why you cannot efficiently run your fuel pressure higher than 32 PSI.

HOW DO WE FIND THE PUMPS DISPLACEMENT?

How do we determine the calculated displacement of this pump. Here is a handy formula to determine cubic inch displacement of any cylinder (pump) or engine. This formula is easy and works great for finding the cubic inch displacement of your engine or any piston pump. Bore x bore x stroke x .7854 x number of cylinders = displacement in cubic inches.

1.180 x 1.180 x .25 x .7854 (constant) x 1 = .273 in³.

For every stroke of the piston, it should produce aproximetely 1/4 cubic inch of fuel flow.

EASY FORMULA TO CALCULATE GPM

We now know that our lift pump displaces .273 cubic inches. How do we figure the calculated GPM flow of the lift pump? The formula is very easy. .273 in³ x pumping cycles per minute (remember that the pump is at half speed of the crank) divided by 231 (cubic inches per gallon of water) = GPM.

.273 x 1250 (half speed of 2500 rated RPM) = 341 divided by 231 = 1.477 GPM. The carter lift pump is calculated at 1.477 (rounded up to 1.48) GPM at 100% efficiency.

AND NOW THE GOOD STUFF!

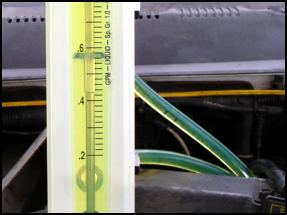

This photo shows the GPM flow at idle, which is 800 RPM. We are now going to use the formulas. Please bear with me, it's straight forward, and rather easy. .3 GPM meter reading x 1.0495 = .315 corrected GPM. This is the actual flow from the Carter lift pump at idle. What is the calculated flow of this piston pump? 400(half engine speed) x .273 cubic inches = 109. 109 divided by 231 (cubic inches in a gallon) = .47 GPM. At 100% efficiency, our lift pump should flow .47 GPM. So, we now take .315 (actual flow) divided by .47 (calculated) = .67 or 67% efficient. Not the best efficiency number, but OK.

This photo shows the GPM flow at idle, which is 800 RPM. We are now going to use the formulas. Please bear with me, it's straight forward, and rather easy. .3 GPM meter reading x 1.0495 = .315 corrected GPM. This is the actual flow from the Carter lift pump at idle. What is the calculated flow of this piston pump? 400(half engine speed) x .273 cubic inches = 109. 109 divided by 231 (cubic inches in a gallon) = .47 GPM. At 100% efficiency, our lift pump should flow .47 GPM. So, we now take .315 (actual flow) divided by .47 (calculated) = .67 or 67% efficient. Not the best efficiency number, but OK.

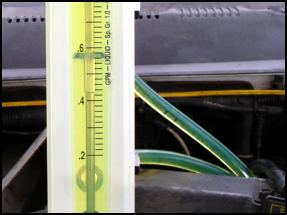

This is the GPM flow at 1500 RPM. My apologies for the faint image. .4 x 1.0495 equals .42 GPM. If this pump were 100% efficient, it would flow .89 GPM. At 1500 RPM our Cummins transfer pump is only 47% efficient. .42 (actual) divided by .89 (calculated GPM flow) = .47 or 47%. Are you starting to see a trend? As the RPM increases, the efficiency goes down !!

This is the GPM flow at 1500 RPM. My apologies for the faint image. .4 x 1.0495 equals .42 GPM. If this pump were 100% efficient, it would flow .89 GPM. At 1500 RPM our Cummins transfer pump is only 47% efficient. .42 (actual) divided by .89 (calculated GPM flow) = .47 or 47%. Are you starting to see a trend? As the RPM increases, the efficiency goes down !!

THE NUMBERS GET WORSE !

At 2500 RPM, we are flowing .52 GPM (.5 x 1.0495 correction) At 2500 RPM, the efficiency has dropped to 35%. That's .07 GPM less than at 2200 RPM. We reached peak flow of .59 GPM at 2200 and everything thereafter is going down hill. If you installed a 4000 RPM governer in your P pump, your fuel flow is in the neighborhood of .44 GPM. My mathematition son, Curtis, arrived at this number by using calculus.

So, our Cummins lift pump is capable of flowing 1.48 gallons per minute of diesel fuel at 2500 RPM. I'm here to tell you that the Carter lift pump is no way near its calculated GPM flow of 1.48. Not even close!! The Carter lift pump only flows .52 GPM at 2500 RPM. That equates to ONLY 35% efficiency. It flows .59 GPM at 2200 RPM, which is 45% efficient. To calculate efficiency take the actual GPM divided by calculated GPM.

.59 divided by 1.3 GPM = .45 or 45% efficient. That's at peak fuel flow. At rated RPM it's much worse!

OUR LIFT PUMP NEEDS HELP!

800 RPM .315 Actual GPM .47 Calculated GPM 67% Efficiency

1500 RPM .42 Actual GPM .89 Calcualted GPM 47% Efficiency

2200 RPM .59 Actual GPM 1.3 Calculated GPM 45% Efficiency

2500 RPM .52 Actual GPM 1.48 Calculated GPM 35% Efficiency

The following numbers were arrived at by using calculus.

4000 RPM .44 GPM 2.36 Calculated GPM 18.6% Efficiency

From an industrial point of view, this lift pump would have to be replaced with a better, more efficient design. Industrial piston pumps are a minimum of 85% efficient. Some models are 90 to 95% efficient. There are several reasons why the efficiency of the Cummins lift pump is so low and it's not the pump's fault !! The secrets on how to improve your fuel system will be revealed in article number three.

When the fuel system on the 94 to 98 Dodge Cummins was designed, they failed to follow basic hydraulic principles. There is no difference between a diesel fuel system and a hydraulic circuit. Both are hydraulic systems! This failure (or intended design to limit HP) is the reason why the lift pump only flows 35% of it's capability at 2500 RPM.

We will cover the reasons why the efficiency goes down as the RPM goes up, and what can be done about it, in article number three. This information series is intended to provide accurate and tested information to the diesel community. Feel free to link to this page and distribute it to your diesel friends.